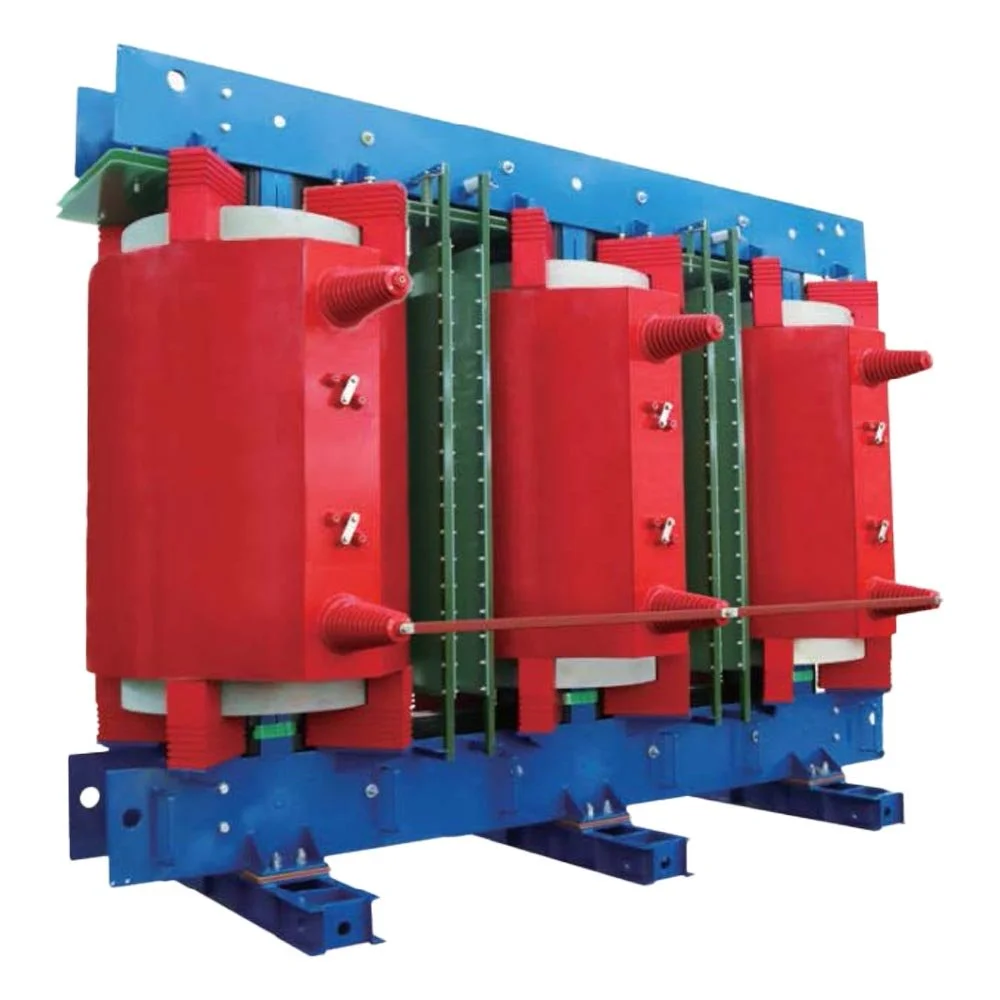

66kV-110kV Oil-Immersed Power Transformer

The product performance is better than the GB/T 6451 three-phase oil-type power transformer technical parameters and requirements in full compliance with JB/T 3837 transformer product model preparation method, the manufacturing standards of GB/T 1094 power transformers and IEC standards recommended by the international electric-technical commission and GB20052-2020 power transformer limited value of energy efficiency level.

Features

The product is characterized by low loss, low noise, anti-leakage and no suspension core. It has extraordinary innovation in safety, reliability, economic efficiency. The transformer's high and medium-voltage tap wires are fixed by a bracket and led to the switch. A low-voltage lead copper wire is fixed onto the upper and lower clamps to improve the stability of lead wire. Besides the coil binding standards and technological process greatly reduce the transformer's partial discharge.These great qualities make this transformer a first-class technical product.

-

Irone core

its iron core adopts multi-step stepping lab-type technology, the laminated piece adopts 45º oblique seam hole-free bandage structure, silicon steel sheet adopts advanced longitudinal and horizontal shear cutting, cutting mouth burr is not than 0.001 inches . The iron core adopts high-strength PET polyester banding design, clip structure adopts plate clamp pieces thus reducing spurious loss. The iron yoke clamp-er adopts a unique clamping banding process, fully guarantees the iron core’s clamping degree.

-

Mechanical Winding

The transformer's high, medium, low and voltage-regulating coil shall wound on an insulating paper tube. Low-voltage winding mainly adopts spiral structure with axial oil passage. High and medium voltage winding are made by composite wire wire wrapped by highstrength DENNISON paper, which is imported from the U.S. That can greatly increase the filling coefficient of transformer’s steel window, reduce the wire’s eddy current loss and circulation loss and also improve the anti-short circuit capacity of the transformer. There are locking stays inside and outside the winding.

-

Body Insulation

The body insulation structure and winding process are completed in a fully sealed clean workshop, can meet the cleanliness requirements and constant body temperature requirements for high voltage, ultra-high voltage transformers and further ensure the cleanliness and dryness of transformer body. Meanwhile, kerosene vapor-phase drying equipment is used to further ensure cleanliness of the body.

Oil Tank: Large and medium transformers adopt bell-type oil tank structure. Large-scale folding machine is used for corrugated molding. Various reinforced iron sheets and reinforced boards are canceled. This not only greatly improves the mechanical strength of oil tank, but also reduces the leakage caused by welding, increases the effective cooling surface of the body and improves the cooling effect.

Cooling feature: It generally adopts air-cooled / self-cooled type and has full-load operation when the fan starts and begin naturally cooling when the fan stops, the load is 67% of full load. Chip radiator shall arranged in a reasonable and compact way, fans are generally hung over radiators, blowing in horizontal or vertical direction. The oil storage tank is generally capsule type, which has an oil-resistant, airtight capsule. It completely isolates from the oil of transformer from the air and achieves full sealing.

Ordering instructions:

1. Product model

2. Rated capacity

3. Voltage combination

4. Voltage regulation range

5. Frequency

6. Label of connection group

7. Short circut impedance

8. Special Requirements

Technical Parameters

〰️

Technical Parameters 〰️

Type 11 66kV Three-Phase Two-Winding No-Excitation Distribution Transformers

Other Models:

Type 11 66kv three-phase two-winding on-load tap changing transformers | 630 – 63000 kva

66kv three-phase two-winding no-excitation distribution transformers | 3150 – 63000 kva

66kv three-phase two-winding on-load tap changing transformers | 6300 – 63000 kva

110kv three-phase two-winding no-excitation distribution transformers | 6300 – 63000 kVA

110kv three-phase two-winding on-load tap changing transformers | 6300 – 63000 kva

110kv three-phase three-winding no-excitation distribution transformers | 6300 – 63000 kva

110kv three-phase three-winding on-load tap changing transformers | 6300 – 63000 kva

110kv low voltage 35kv three-phase two-winding no-excitation distribution transformers | 6300 – 63000 kva

Type 11 110kv three-phase three-winding no-excitation distribution transformers 630 – 63000 kva

*Note: The parameters are different for each model. If you have any questions about a specific model, kindly reach out to murat@ryantransformer.com